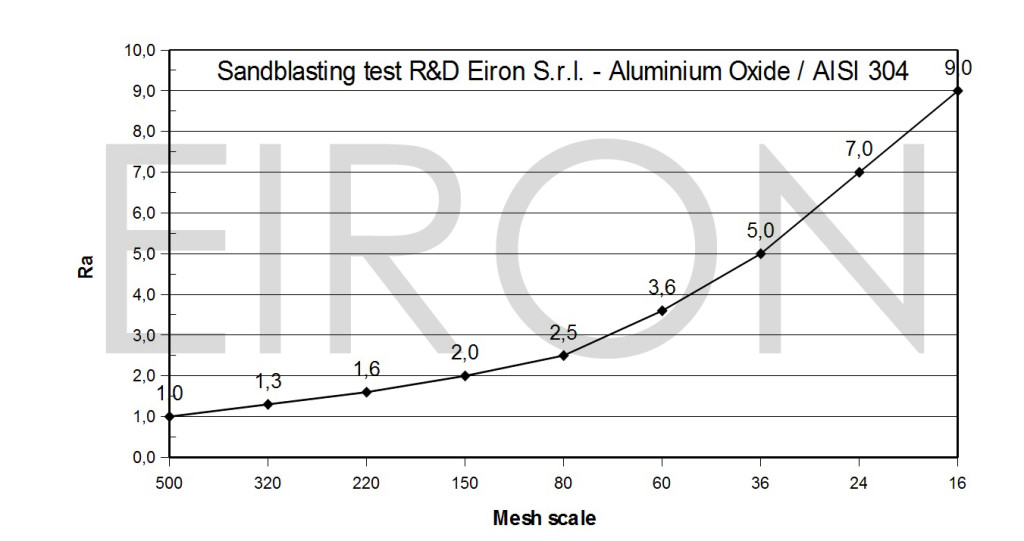

CONTROLLED ROUGHNESSThe technological progress and the introduction of new coating technologies such as PVD (physical vapor deposition), CVD (chemical vapor deposition), APS (air plasma spray), VPS (vacuum plasma spray), chemical nickel plating, hard chrome plating, metal-rubber anchors have enhanced the importance of surface treatment in terms of use and strength of materials. Anyone involved in the coating industry, cannot do without having a good adhesion between the support and the coating. Each type of coating has a specific surface anchoring level which leads to the optimal performance and durability. Depending on the coating technology, the surface roughness produces a distinct phenomena, which strongly influences the quality of the final product. For any further information please do not hesitate to contact us. ROUGHNESS WITH ALUMINIUM OXIDEADVISED GRIT

AREAS OF USE |